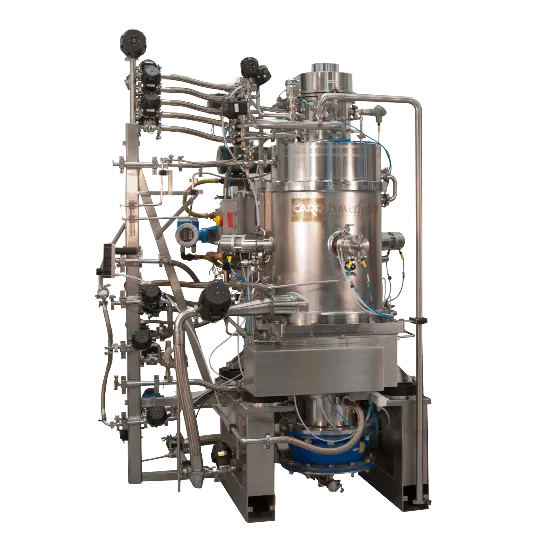

PowerFuge® P18: A Stainless Steel System for Maximum Processing

Streamline long-term high-throughput processing with the PowerFuge P18. With its larger bowl volume and higher flow rate, this CIP/SIP automated large-scale centrifuge is best suited for high-capacity applications that require maximum throughput.

| Minimum Working Volume 36 L | Flow Rate 10 L/min | G-force Up to 20,000 xg |

Benefits of CARR Biosystems PowerFuge P18

Versatility

Transition from development to manufacturing, handling applications like E. coli harvest, lysate removal, P. pastoris clarification, specialty chemicals, and solvent separations.

Performance

Handle even the most challenging separations with the ability to process bacteria, fungi, proteins, and submicron particles using a large-scale centrifuge with 20,000xg separation force and a closed system design.

Durability

Reduce downtime and maintenance costs with robust construction, high-quality materials, comprehensive maintenance, and CIP/SIP capabilities, ensuring fewer parts to replace and longer operational life.

High-Throughput

Efficiently process large volumes with the PowerFuge P18, the biggest and fastest of the PowerFuge family, featuring a generous bowl volume and full automation for a quick turnaround at scale.

The PowerFuge P18 is the largest of the PowerFuge automated centrifuge family. Its titanium-alloy tubular bowl enables low-shear, high-throughput liquid-solid separation of bacterial, fungal, protein, and submicron particles. The PowerFuge P18 handles high-density feeds without dilution to maximize product yield while also automating solids removal for improved efficiency.

- Complete liquid/solid separations

- Full Clean-In-Place/Sterilize-In-Place (CIP/SIP)

- Fully automated processes, including solids removal

- Integrated cooling jacket & spindle cooling unit

- Regulatory documentation available

- Closed processing system

| Rec. Processing Volume | 250-2,000 L |

| Max Flow Rate | Up to 28 L/min |

| Rotational Force | Up to 20,000 xg |

| Max Concentrate Density | <1.5 g/ml |

| Weight | 1,950-4,400 kg (6,500-9,700 lbs) |

| Maximum Case Pressure | 1 bar (non-SIP), 2 bar (SIP, ASME/PED) 6.9 bar (100 psi) cooling jacket |

| Programmable Logic Controllers (PLC) | Allen-Bradley® or Siemens® |

| Feed | Feedcone acceleration |

| Electrical Requirements | 400V/50Hz or 480V/60Hz (configuration dependent) Spindle cooling unit: 230V/50Hz |

| Pneumatic | Clean, dry air supply 6 bar (90 psi), 566 Standard Liters per Minute (SLPM), 20 Standard Cubic Feet per Minute (SCFM), Instrument-quality air only, supplied at 80-100 psi |

Process Wetted Parts Construction

- 316 and 316L stainless steel

- 17-4PH stainless steel

- Nitronic 60 stainless steel

- High-strength titanium alloy

- Teflon, silicone, ethylene propylene diene monomer (EPDM) O-rings and gaskets

- Stainless steel finish: electropolish (25 RA)

- Titanium alloy bowl tumbled finish: (25 RA)

- Swinglock rollers of polyether ether ketone (PEEK) thermoplastic

The PowerFuge is a continuous flow centrifuge that introduces the feed through a stationary pipe and accelerates it to full rotational speed before entering the titanium-alloy tubular bowl. Centrifugal forces separate solids from liquids, compressing solids against the bowl wall while the supernatant flows into a collection chamber. Compressed solids are periodically removed with a fully automated scraping cycle.

The PowerFuge P18 features:

- Service hoist

- Fully automated, intuitive software accessible through Allen-Bradley HMI touchscreen

- Siemens HMI touchscreen available

- Optional hazardous duty (Class 1, Div 1, Group C and D) and CE configurations available

- Designs available for ASME and PED rated boundary, hazardous locations, and aseptic operations

- Closed processing system for solvents and hazardous materials

Endorsements

See What People Are Saying About Our Stainless Steel Centrifuges

Scale up or down with PowerFugeⓇ

Our PowerFuge family enables efficient liquid-solid separation. Its durable stainless steel construction handles bacteria, fungi, proteins, and submicron particles from small to large-scale applications.

Frequently Asked Questions (FAQs)

What is the maximum processing speed of the PowerFuge P18, and how does it benefit my operations?

The PowerFuge P18 can achieve a typical processing rate of 10 liters per minute. This high-speed capability allows for efficient and rapid separation of solids and liquids, making it ideal for demanding, larger-scale applications that require quick turnaround times and high throughput.

How does the large bowl volume of the PowerFuge P18 enhance its performance?

The PowerFuge P18 features a substantial bowl volume of 36 liters. This large capacity enables the processing of significant volumes of feed material, reducing the need for frequent batch changes and enhancing overall productivity. The spacious bowl design also ensures effective separation, even with high-density feeds, without dilution, maximizing product yield.

What are the key features of the PowerFuge P18 that make it suitable for automated and rigorous environments?

The PowerFuge P18 is equipped with full automation capabilities, including automated solids removal and CIP/SIP functions. These features streamline operations by minimizing manual intervention and ensuring thorough cleaning and sterilization between batches. Additionally, the PowerFuge P18 includes an integrated cooling jacket and spindle cooling unit to maintain optimal operating temperatures, as well as a service hoist for easy maintenance. The large-scale centrifuge's robust construction, regulatory documentation availability, and multiple design options further enhance its suitability for various industrial applications.

Stay Connected

Contact Us

Get in touch with a sales representative, request support or download our free white paper.

Contact Us