UniFuge Pilot®:

A Single-Use System for Cell Processing

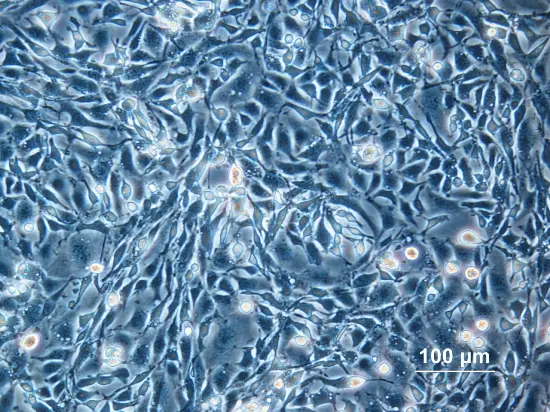

Achieve high separation efficiency and up to 98% cell viability in early-stage development with the UniFuge Pilot automated centrifuge. Optimize low-shear, high-throughput processing of mammalian, bacterial, and insect cells for pilot-scale production that scales up or down easily.

| Minimum Working Volume 1.8 L | Flow Rate 1-4 L/min | G-force Up to 4,000 xg |

Benefits of CARR Biosystems UniFuge Pilot

Versatility

Increase cell recovery and efficiency across multiple applications with low-shear, high-throughput processing in the early stages of development.

Performance

Improve your product yield and purity with the UniFuge Pilot’s tubular bowl centrifugation, enabling low-shear separation of even the most fragile cell types.

Reproducibility

De-risk the scale-up and tech transfer process with intuitive software, technical automation, and reduced operational costs.

Optimization

Maximize quality and reduce waste with the UniFuge Pilot’s closed system, small residual volume, and low absorption, ensuring more product from less culture volume.

The UniFuge Pilot has a lightweight single-use module (rotor and separation chamber) and integral tube set that comes pre-gamma irradiated to ensure easy installation, clean-up, and disposal. These sterile connections can be fitted to existing setups upon request.

- Low noise level (below 80 dB) during operation

- Continuous discharge of supernatant and intermittent discharge of cell culture

- Reduces host cell proteins and other contaminants

- Compatible with various processing volumes and concentration targets

- Different jacket options are available

| Rec. Processing Volume | 25-500L |

| Max Flow Rate | 1-4L/minute |

| Rotational Force | 300 to 4,000 xg |

| Weight | 291 kg (690 lbs) |

| Maximum Case Pressure | 6.9 bar (100 psi) |

| Programmable Logic Controllers (PLC) | Allen-Bradley® |

| Feed | Center for low-shear operation |

| Power Configurations | 120/230 Volts Alternating Current (VAC), 50/60 Hz, Single-Phase (1-Ph), 10 A |

| Pneumatic | Clean, dry air supply 4.5-6.6 bar (65-95 PSI), 57 Standard Liters per Minute (SLPM), 2 Standard Cubic Feet per Minute (SCFM) |

Single-Use Module

- Components compliant with physiochemical tests: intermittent discharge of cell culture: USP <87> <88> Class VI, USP 661 (or ISO 10993) for plastic materials

- Concentric tubes to introduce feed and remove supernatant

- Compliant with ISO 11137 to Sterility Assurance Level (SAL) 10-6

Balancing centrifugal forces and fluid flow rates, the UniFuge cell processing platform gently concentrates cells in the tubular bowl while the supernatant (cell-free media or buffer) flows into a collection chamber. The concentrated cells can then be washed or exchanged with another medium or buffer within the same closed chamber. Once the module fills with cells, the controller stops the rotor to automatically collect the cell concentrate. This cycle repeats until cell processing is complete.

The UniFuge Pilot features:

- Fully automated, intuitive software accessible through a PLC color touchscreen

- Optional Supervisory Control and Data Acquisition (SCADA) via Ethernet connection

- cGMP compliance with standards, including Federal Regulations (21 CFR Part 11) data trail

Endorsements

See What People Are Saying About Our Single-Use Centrifuges

Scale up or down with UniFuge®

Our UniFuge cell processing platform enables low-shear separation and improves cell recovery throughout development and commercialization.

*Processing speeds are application dependent and may vary.

**Weights and dimensions are dependent on system configuration and options required.

Featured Resources

Frequently Asked Questions (FAQs)

How big is the UniFuge Pilot, and can it be moved easily?

The UniFuge Pilot is 61cm wide x 99cm deep x 117cm high (24” x 39” x 46”) for a small bench footprint and has a total weight of 291kg (640 lbs), making it easily movable with stainless steel casters leveling on skid with vibration isolators.

What are the utility requirements for the UniFuge Pilot centrifuge?

- Power configurations: 120/230 VAC, 50/60 Hz, 1 Ph, 10 A

- Optional: 120 VAC, 50/60 Hz, 1 Ph, 20 A

- Pneumatic: Clean, dry air supply 4.5-6.6 bar (65-95 PSI), 57 SLPM (2 SCFM)

How does the UniFuge Pilot centrifuge perform?

UniFuge Pilot is one of our high-performance single-use centrifuges. It has a Packed Cell Volume (PCV) of up to 25% and can achieve a cell viability rate and yield of 98%. The UniFuge Pilot’s software and automation minimize process errors, and its single-use modules can be rapidly switched out after each use to keep your projects running.

Stay Connected

Contact Us

Get in touch with a sales representative, request support or download our free white paper.

Contact Us