U2k®: A Single-Use System for Scaling Up Cell Processing

Preserve cell health during high-throughput primary clarification and harvesting with the high-capacity U2k® centrifuge. Improve productivity without compromising cell viability with low-shear processing for large-scale production and commercialization.

| Minimum Working Volume 9 L | Typical Flow Rate 5-20 L/min | G-force Up to 3,000 xg |

Benefits of CARR Biosystems U2k

Efficiency

Streamline cell processing with intuitive software and full automation, reducing operational costs and enhancing process intensification.

Performance

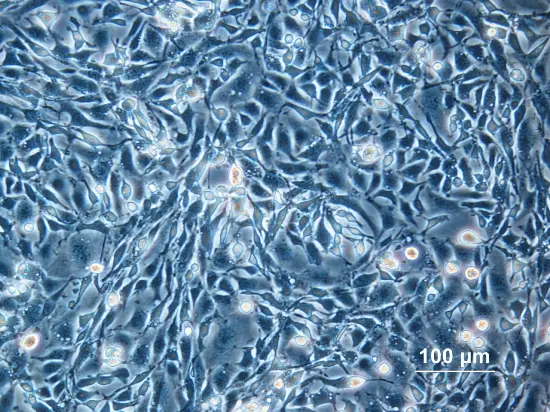

Improve your product yield and purity with the U2k’s tubular bowl centrifugation, enabling low-shear separation of even the most fragile cell types.

Versatility

Increase cell recovery and efficiency across multiple applications with low-shear, high-throughput processing in the later stages of development.

Capacity

Process hundreds of liters of product per hour with the high-capacity U2k—maximize cell recovery and product output for large-scale production.

The U2k is a scaled-up version of the UniFuge Pilot, perfect for the later stages of development. It has a single-use module (rotor and separation chamber) and integral tube set that comes pre-gamma irradiated to ensure easy installation, clean-up, and disposal. These sterile connections can be fitted to existing setups upon request.

- Low noise level (below 80 dB) during operation

- Intermittent discharge of supernatant and cell culture

- High cell density (up to 25% PCV)

- Compatible with various processing volumes and concentration targets

- Integrated cooling jacket

| Rec. Processing Volume | 500 - 2,000L |

| Max Flow Rate | 5-20 L/min |

| Rotational Force | 500 to 3000 xg |

| Weight | 912 kg (2010 lbs) |

| Maximum Case Pressure | 6.9 bar (100 psi) |

| Programmable Logic Controllers (PLC) | Allen-Bradley® or Siemens® |

| Feed | Center for low-shear operation |

| Power Configurations | Three-phase voltage supply US: 230V/60 Hz, 80A or 460V/60 Hz, 40A Europe: 400V/50 Hz, 46A Japan: 200V/60 Hz/50 Hz, 90A Others as needed |

| Pneumatic | Clean, dry air supply 6.2-8.3 bar (90-120 PSI), 100 Standard Liters per Minute (SLPM), 3.5 Standard Cubic Feet per Minute (SCFM) |

Single-Use Module

- Module minimum working volume 9L with 9.5mm (3/8”) inner diameter x 12.7mm (1/2”) outer diameter silicone tubing

- Physiochemical: USP <87> <88> Class VI, USP 661 (or ISO 10993) for plastic materials

- Concentric tubes to introduce feed and remove supernatant

- Manufactured in ISO 13485 facility with Class 7 cleanroom

Balancing centrifugal forces and fluid flow rates, the UniFuge cell processing platform gently concentrates cells in the tubular bowl while the supernatant (cell-free media or buffer) flows into a collection chamber. The concentrated cells can then be washed or exchanged with another medium or buffer within the same closed chamber. The U2k is also capable of cell discharge for clarification applications.

The U2k features:

- Fully automated, intuitive software accessible through a PLC color touchscreen

- Optional Supervisory Control and Data Acquisition (SCADA) via Ethernet connection

- cGMP compliance with standards, including Federal Regulations (21 CFR Part 11) data trail

Endorsements

See What People Are Saying About Our Single-Use Centrifuges

Scale up or down with UniFuge®

Our UniFuge cell processing platform enables low-shear separation and improves cell recovery throughout development and commercialization.

*Processing speeds are application dependent and may vary.

**Weights and dimensions are dependent on system configuration and options required.

Featured Resources

Frequently Asked Questions (FAQs)

What is the capacity range of the U2k?

The U2k single-use centrifuge offers a flexible capacity range (500-2,000L) suitable for various scales of operation. It is designed to handle volumes from small-scale research and development to pilot-scale production, providing a seamless transition to larger scales.

What types of cells can be cultured in the U2k single-use centrifuge?

The U2k is versatile and can accommodate a wide range of cell types, including microbial, mammalian, plant, and insect cells. It is particularly well-suited for applications requiring high-density cell cultures and high-yield product outputs, with a PCV of up to 25%.

What are the key features of the U2k that support productivity?

The U2k enhances productivity through advanced control systems that automate the monitoring and adjustment of critical parameters, ensuring optimal conditions for cell growth. Its single-use modules ensure sterility, and the U2k design supports high cell densities, maximizing yield. Additionally, the U2k's real-time data logging and advanced software facilitate seamless scale-up and fine-tuning of the bioprocess to achieve optimal results and scale to production and commercialization.

Stay Connected

Contact Us

Get in touch with a sales representative, request support or download our free white paper.

Contact Us