Enhanced Cell Viability

- Low-shear separation to preserve cell health

- Efficient cell washing and buffer exchange to remove spent media or reagents

- Optimal cell reproduction rates through gentle processing

Optimize cell agriculture workflows with versatile, gentle cell handling for consistent scalability and efficiency. Achieve high viability and tunable processing from lab to full-scale production with the UniFuge® single-use platform and ViaFuge® for SIP/CIP applications.

UniFuge and ViaFuge centrifuges use low-shear, tubular bowl technology to preserve cell health, promoting high reproduction rates and improved viability. The UniFuge supports versatile scale-down for development, while the ViaFuge, designed specifically for cell agriculture and perfusion, provides automated, non-disposable, high-throughput processing, making both models adaptable for various stages of production.

Connect with an Expert

Gene EditingGentle separation concentrates cells and exchanges media, preserving cell integrity for efficient gene editing. |

Cell ExpansionLow-shear separation supports high cell reproduction rates, allowing cells to expand without compromising viability. |

Perfusion & Media ExchangeContinuous perfusion and automated exchange maintain optimal conditions by removing waste and refreshing media. |

Continuous HarvestLow-shear, continuous harvesting maintains cell viability while enabling uninterrupted downstream processing for efficient workflows. |

Cell HarvestCareful separation gently concentrates cells, minimizing damage with optional washing to enhance purity. |

Cell Banking & StorageGentle handling prepares cells for storage, ensuring high viability and reducing contamination risks during future use. |

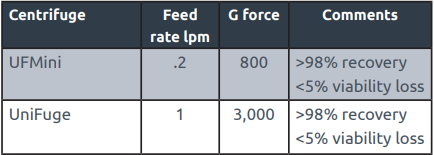

The UniFuge Pilot and UniFuge Mini deliver over 98% cell recovery with less than 5% viability loss in bovine cells, demonstrating efficient cell intensification with gentle processing and supporting similar results across various cell types.

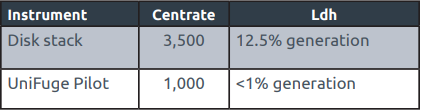

The UniFuge Pilot maintains cell integrity through low-shear processing, reducing LDH release to under 1%. This is significantly lower than traditional disk stack systems, which produce up to 12.5% LDH, which indicates cell stress.

The cell agriculture industry requires scalable methods to gently harvest and clarify various animal cells (e.g., chicken, salmon, bovine) from complex growth media without compromising cell viability or recovery.

CARR Biosystems collaborated with cell agriculture scientists to test the UniFuge platform in optimizing cell harvesting parameters for different cell types. By adjusting the feed rates and g-forces, the centrifuges were evaluated for compatibility with different cell densities and production needs.

The UniFuge platform delivered:

CARR’s centrifuges, including the UniFuge and ViaFuge series, are designed to achieve high recovery rates, often exceeding 90% depending on the specific cell type and process parameters.

CARR centrifuges, available in both single-use and stainless steel models, are designed to minimize contamination risks. The single-use UniFuge platform offers a closed, contamination-free environment, ideal for sterility-sensitive applications. For stainless steel models, like ViaFuge, features like clean-in-place (CIP) and steam-in-place (SIP) ensure effective sterilization and support ongoing sterility in continuous production environments.

Yes, CARR’s UniFuge series supports scalability from small-bench scale through to pilot and full-scale production. The range of models allows users to develop processes at smaller scales and seamlessly scale up to higher capacities.

Get in touch with a sales representative, request support or download our free white paper.

Contact Us