In the ever-changing landscape of cultured meat, or cell-based meat, CARR Biosystems is actively engaged in exploring sustainable solutions for future food production. Through interactions with a range of stakeholders, including biotech entrepreneurs and venture capitalists, we've gained valuable insights into the industry's trajectory. Here we highlight our perspective on key factors influencing the industry’s direction and success:

The Diversity of Cultured Meat Applications

The potential applications of cultured meat span a wide spectrum. Some companies aim to produce a ground meat-like product without creating the look of a familiar cut, while others are deeply invested in state-of-the-art technology to produce delicacies that create the look, taste, and texture of perfect sashimi. This varied approach highlights the extensive potential and diverse market demands within the industry. It requires diversity in manufacturing processes and technologies to achieve the unique needs of each target product and its critical attributes.

The Enigma of Post-Bioreactor Processing

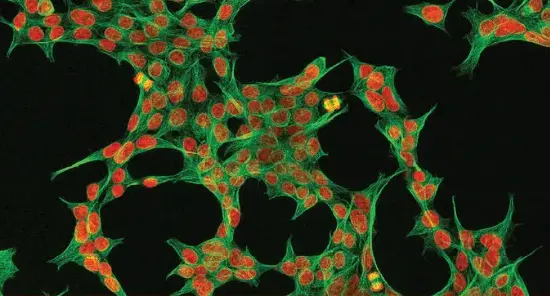

A significant step following cell cultivation in bioreactors is morphing those cells into a palatable meat product. After cells have been cultured and multiplied in a bioreactor, the next step is to harvest them for further processing. Centrifugation allows scientists to efficiently collect and concentrate the cultured cells, facilitating downstream processes such as direct creation of meat products or further upstream processing including 3-D culture for tissue formation. Scalable continuous centrifugation technologies provide process development and manufacturing engineers continuity as they bring production processes from several to thousands of liters. This helps to streamline the production process and ensures that the final cultivated meat product has the desired texture and structure. Choosing the right harvesting solution is crucial for high cell viability in lab-grown meat. In our next post, the importance of high cell viability is discussed in further detail.

Several enterprises have adopted the approach of placing harvested cells on scaffolds, allowing them to grow and assume a structure reminiscent of meat. The variety of these scaffolds is vast, encompassing everything from vegetable-based solutions to innovative edible plastics; however, one commonality among all scaffold-based cultured meat products is the importance of cell viability and health during the bioreactor harvest. A distinction here between viable and healthy cells is important to note, as cells found viable by common methods do not necessarily indicate they are ‘healthy’ and capable of growing as expected on a scaffold or during other subsequent culture steps.

Achieving Scale

Traditional batch processing methods in bioreactors, while effective for smaller-scale operations, struggle to meet the efficiency and output needed for larger-scale production. This inefficiency is amplified when considering the perishability of meat products, which requires efficient production and distribution to ensure freshness and quality.

Enter the concept of continuous harvest – a transformative approach that significantly increases the productivity of each bioreactor. Unlike batch processing, continuous harvest allows for the constant removal of cells from the bioreactor, ensuring a steady production flow. This method not only maximizes the output per volume of cell culture but also reduces the overall volume of culture needed. Consequently, this can pave the way for smaller, more regional manufacturing hubs. Such a decentralized model of production aligns perfectly with the need to reduce long-distance transportation of perishable goods, ensuring fresher products reach consumers more quickly and sustainably. Furthermore, regional hubs can adapt more responsively to local market demands, reducing waste and improving supply chain efficiency in the burgeoning cultured meat industry.

Three Pressing Challenges Facing the Industry

- Market Acceptance: The pivotal question remains: Will the wider consumer market embrace cultured meat? Preliminary surveys suggest a willingness to try among half respondents1. However, continuous loyalty and adoption are still under scrutiny. Long-term success hinges largely on sustained consumer trust and acceptance.

- Cost Competitiveness: Achieving a cost structure for cultured meat that parallels, if not undercuts, traditional meat is a colossal challenge. The lifeline here is robust venture capital backing, propelling research and enhancing production scales. If cultured meat maintains a premium price tag over traditional alternatives, mainstream acceptance could be elusive.

- Navigating Scale-up Complexities: While the industry has seen encouraging successes, the amplification of production for commonly consumed meats remains a daunting task. Overcoming the scientific and logistical hurdles will determine the industry's ability to meet global demand.

In summation, while CARR Biosystems recognizes the transformative potential of cultured meat, the path is interspersed with scientific, economic, and societal challenges. Addressing these effectively can elevate cultured meat from a niche alternative to a staple food source, especially in regions constrained by agricultural resources. The next epoch of food might very well be gestating in a laboratory near you.

References

- Rolland, N. C., Markus, C. R., & Post, M. J. (2020). The effect of information content on acceptance of cultured meat in a tasting context. PLoS One, 15(4), e0231176.